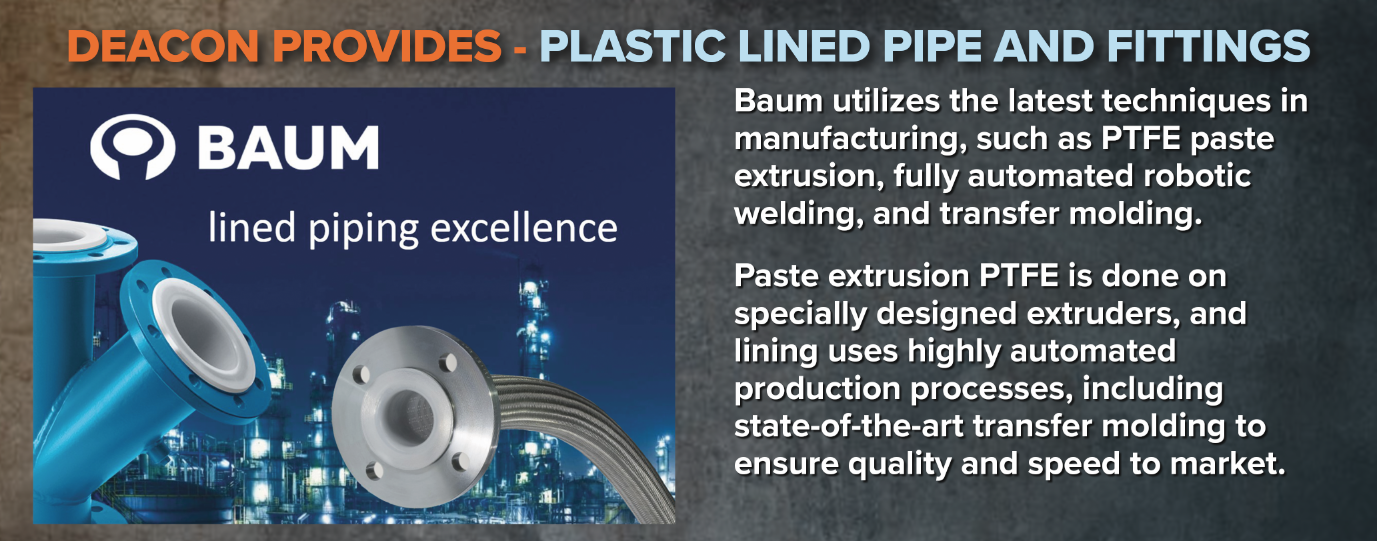

BAUM AMERICA CORPORATION

Manufacturers of high-quality plastic lined carbon steel and stainless steel

pipe, fittings, vessels, dip tubes, valves, and expansion joints that protect the

steel from corrosion using PTFE, PFA, ETFE, PVDF, or PP.

pipe, fittings, vessels, dip tubes, valves, and expansion joints that protect the

steel from corrosion using PTFE, PFA, ETFE, PVDF, or PP.

Manufacturers of high-quality plastic lined carbon steel and stainless steel

pipe, fittings, vessels, dip tubes, valves, and expansion joints that protect the

steel from corrosion using PTFE, PFA, ETFE, PVDF, or PP.

pipe, fittings, vessels, dip tubes, valves, and expansion joints that protect the

steel from corrosion using PTFE, PFA, ETFE, PVDF, or PP.

CUSTOM LENGTH LINED PIPE FABRICATION BEGINS WITH DEACON

CUSTOM LENGTH LINED PIPE FABRICATION BEGINS WITH DEACON

BAUM handles the complete production of its product line, and ALL of BAUM’s products are put through the most stringent quality inspections to comply with ASTM f1545-15a specifications.

BAUM FEATURES AND BENEFITS

INCLUDE:

-

Baum PTFE liners are paste extruded,

ensuring permeation resistance that

exceeds the isostatically molded PTFE

products common from other providers -

Many of the fittings BAUM produces

use injection molded PFA resulting in

full penetration welds unlike the

welded over products. -

Baum metal housings feature rotating

A105 forged steel flanges as standard.

Other manufacturers typically charge

for similar upgrades. -

Quality is verified by rigorous testing

and assured with Insurance company

certification. The Pressure Equipment

Directive (PED) requires not only

participation in an ISO quality program

but 100% traceability, spark and hydro

testing, constant batch testing, and

permanent marking.